New Machine Tool Day

Introduction

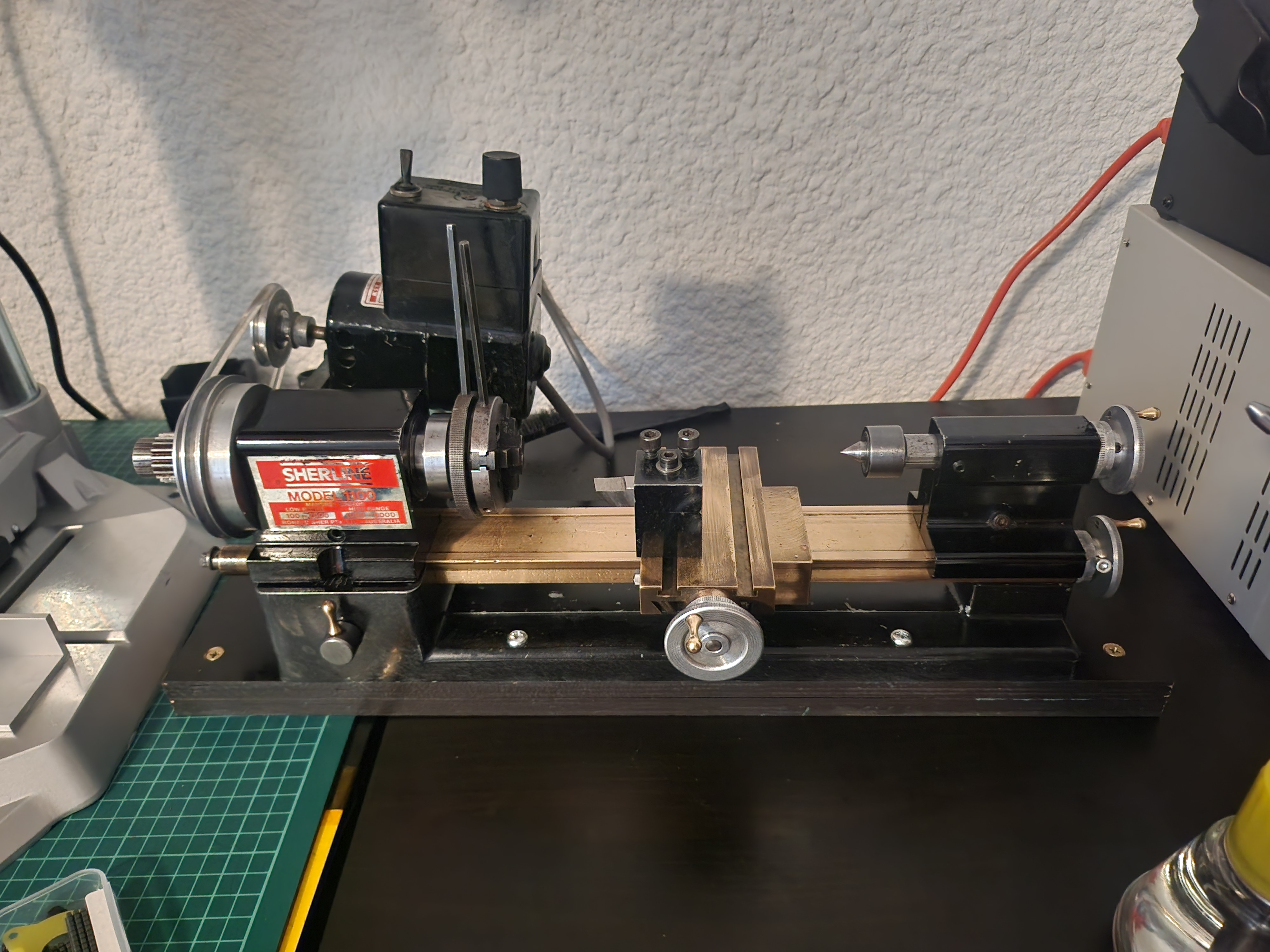

I bought a lathe — a Sherline Model 1100 from 1972 — for 140 CHF (an absolute steal). Made in Australia (shout-out to the Aussies).

But first things first…

Materials & Tools Needed 🛠️

Nothing fancy here — just the basics:

| Tools | Materials |

|---|---|

| Screwdrivers | Shop Towels |

| Pliers | Solvent (e.g., WD-40) |

| Wirebrushes | Whale Oil (ISO-68) |

| Scotch-Brite |

Cleaning Up 🧼🫧

Disassembling this beast is mandatory before cleaning. Here’s the process:

4. Lamp

5. Lathe Chuck

6. Handwheels

7. Tail Stock

8. Cross Slide

9. Headstock

10. Bed Ways

Once everything was disassembled, it was time to clean, oil, and reassemble.

Oiling 🛢️

Use ISO-68 (HLP-68 is basically the same stuff), also known as Whale Oil 🐋

Chuck

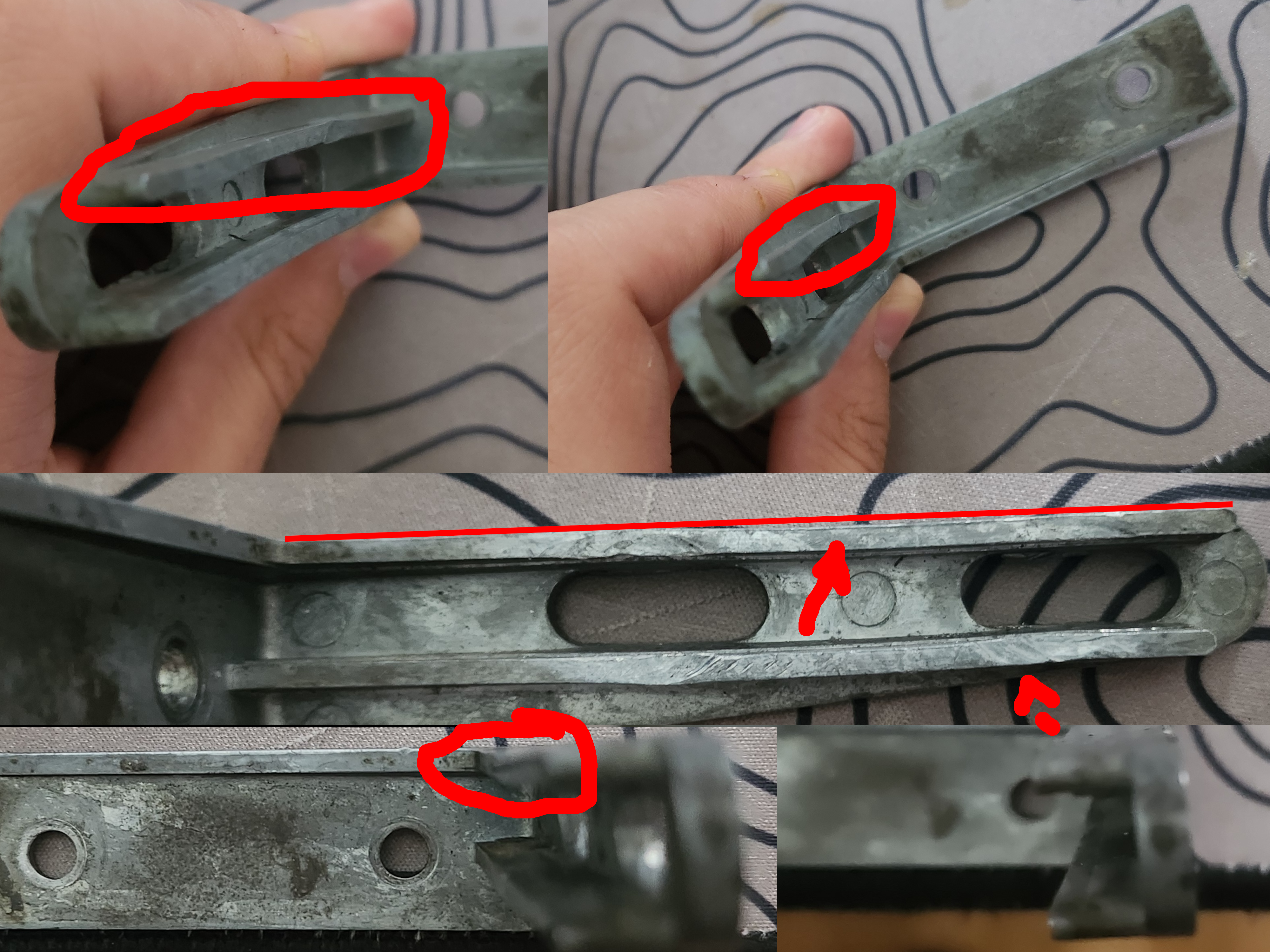

The chuck should have been the easiest part to clean, but it turned into the hardest because of a stuck backplate. I put it aside until the rest of the lathe was back together.

It took me two hours to remove the threaded backplate — it was absolutely packed with crud. A bit of WD-40 helped once it was fully disassembled.

Tiny gaps made by prying the backplate

Tiny gaps made by prying the backplate

Backplate Removed — Full of Crud

Backplate Removed — Full of Crud

Once removed, the circlip had to go.

Warning: Don’t use the wrong tool for circlips.

Get a proper circlip (snap-ring) pliers. They’re one of those tools you rarely need, but when you do, nothing else works.

Pro Tip: For a one-off job, buy the cheapest tool you can find. If you end up using it often, then upgrade to a better one.

3-Jaw Chuck Dissassembled & Cleaned

3-Jaw Chuck Dissassembled & Cleaned

Here is the lathe cleaned and reassembled:

Repair 🔩

A separate blog post will cover the full repair process, but here’s what I’ve done so far.

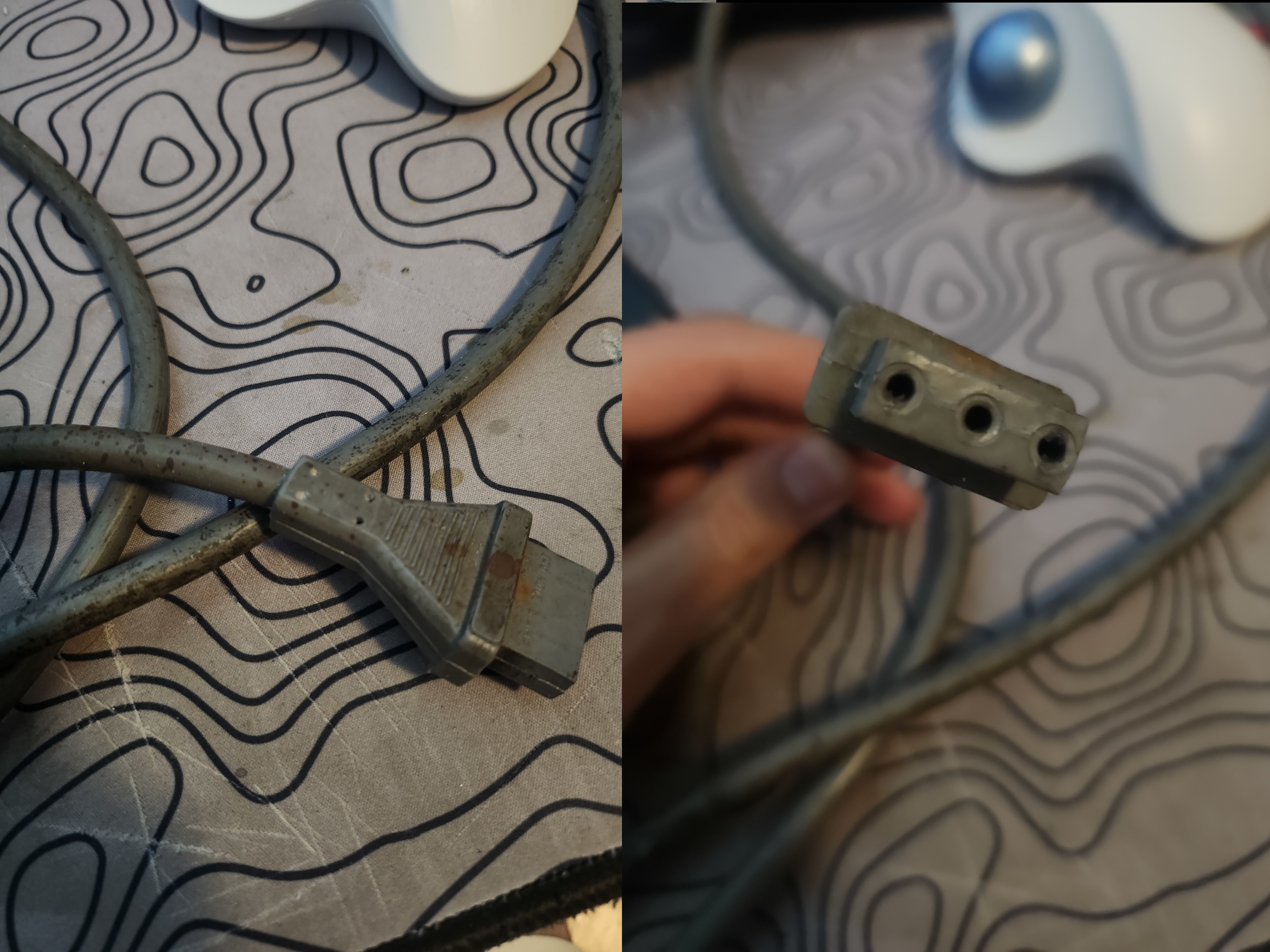

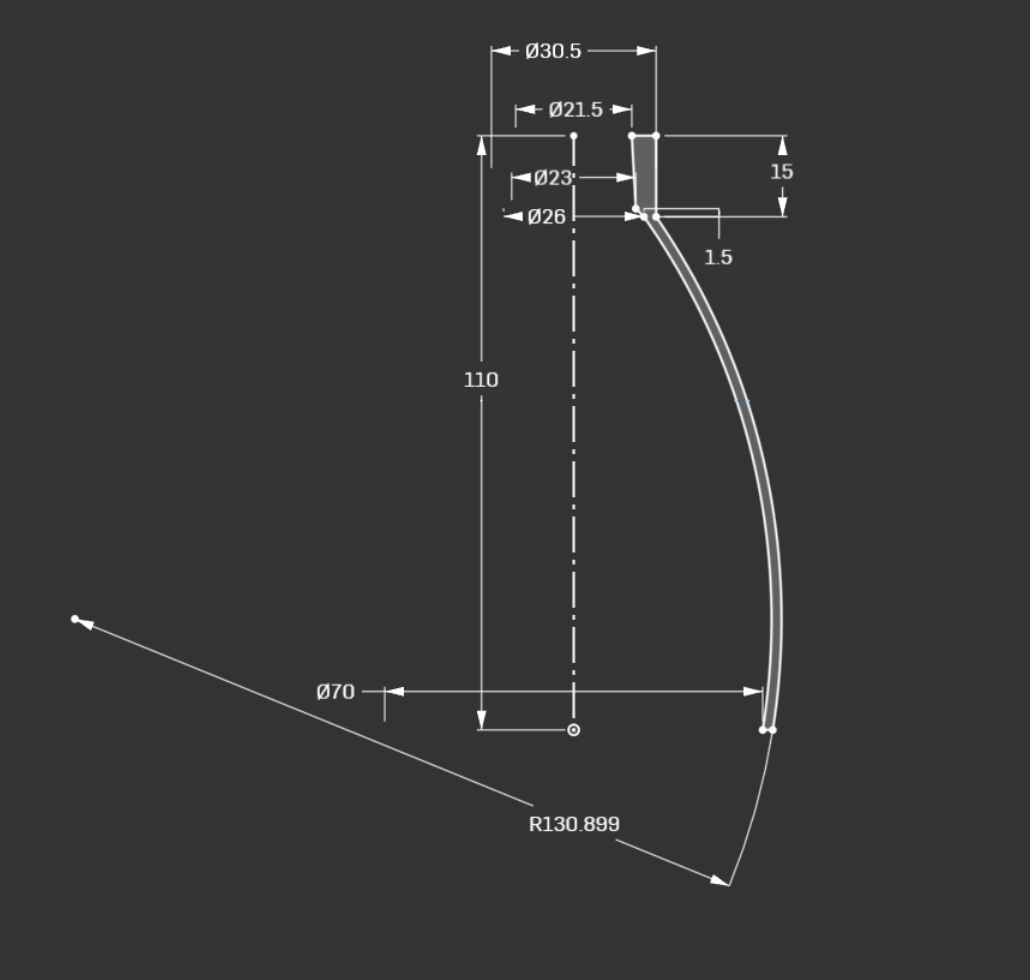

The lathe came with a lamp. The bulb had exploded during shipping, the shade was broken, the wiring was sketchy, and the 230 V cable had no switch. I rebuilt the entire lamp from scratch: bought an E14 bulb, a proper cable, and then pulled up CAD for the design.

No paper sketch this time 😭 (my notebook is full — need a new insert). The design was straightforward.

Designing & Prototyping 🖥️

Here’s the main sketch, based on a revolve extrusion:

Finishing Touches ✨

The lathe came with this board with non-slip pad although the screws didn’t screw into place, so i replace them with one i got in my stock

Baseplate that came with the Lathe

Baseplate that came with the Lathe

Lathe Oiled, and Cleaned and assembled

Lathe Oiled, and Cleaned and assembled

To-Do List 📝

There’s still a lot to fix:

- Motor mount bracket — seller didn’t remove the motor for shipping, so it’s sagging badly

- Replacement belt — current one is a cheap welded type with a broken joint

- Backlash on the carriage — currently two full turns (!), should be ~¼ turn according to Sherline

- Make tooling

- Make a backsplash

- Fix chuck jaw placement guide in the manual

- …and more to come

Note: Everything was done while listening to BONES’ latest album DUNGEON go check it out!

Cost Breakdown 💰

| Item | Quantity | Unit Cost | Total Cost |

|---|---|---|---|

| E14 Bulb | 1 | CHF 8.40 | CHF 8.40 |

| Light Switch | 1 | CHF 1.20 | CHF 1.20 |

| E14 to 240V Cable | 1 | CHF 8.95 | CHF 8.95 |

| Cable | 1 m | CHF 12.50/10 m | CHF 1.25 |

| Crimp | 4 | CHF 0.50 | CHF 2.00 |

| 3D Filaments | 50 g | CHF 30.00/kg | CHF 1.45 |

| Whale Oil | 1 L | CHF 9.40 | CHF 9.40 |

| WD-40 | 1 can | CHF 12.50/300 ml | CHF 12.50 |

| Shop towel | A lot | CHF 2.50 | CHF 2.50 |

| Grand Total | CHF 47.65 |

Conclusion 🎯

Here are some tips to save you headaches:

- Watch out — not all sellers understand basic shipping safety

- Don’t rush — it’s better to do it right once than redo it later because you messed up